Applications in Heat Engineering and Power Industry

Temperature and thermal energy measurement

We manufacture temperature sensors for heat meters and industrial sensors and also heat meter calculators (for water or steam).

We perform metrological testing and legalizations of heat meters parts

Billing systems for utilities consumption (heat energy, electric energy, water, technical gases, compressed air).

We design and install systems for billing and optimization of energy and other utilities consumption enabling also full analysis of important parameters and measurement data archiving.

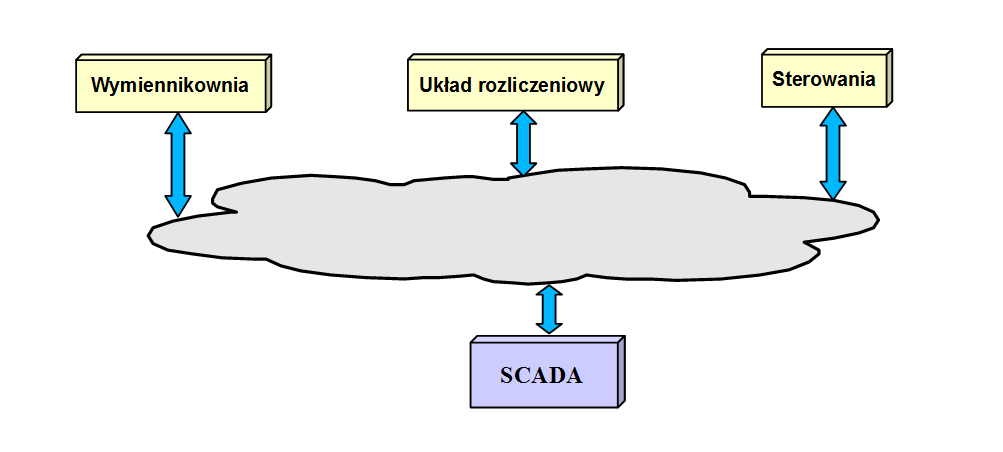

Control, monitoring and visualization of measurement data in SCADA systems for heat networks

Heat networks:

Facilities:

- heat sources (heat generation plants),

- heat exchanger rooms,

- billing systems,

- network control system (slide dampers, valves).

In case of heat sources we ensure proper metering of heat stream “output”, internal load boilers, control of boilers and hydraulic systems, as well as complete automation of boilers.

Main benefits are significant energy savings allowing quick return of the investment costs and comprehensive, current, automated control of boiler room operation (quick detection of all irregularities of devices operation).

In heat exchanger rooms we install supplied heat billing systems (High Parameters) and removed heat billing systems (for ex. central heating, central hot water) based on legalized heat meters, whereas facility control is executed based on programmable or dedicated controllers.

All data from the object are integrated together by means of programmable data concentrators and data transfer is performed by optimum transfer medium enabling sending several commands to the controllers.

Heat billing systems require only optimum configuration of data transmission from heat conversion devices, what can be done by means of programmable data concentrators.

GSM transmission (GPRS) is used for this purposes very often, with accumulation of local readings.

Obvious benefit of such solution is reduction of costs of measurement system operation and heat supply billing, including maintenance services (measurement data are read and sent automatically and then automatically processed by proper information technology system. Remote monitoring enables quick detection, registration and diagnostics of breakdowns or failures and their remote solving in some cases.

Large control systems are used mainly for remote re-configuration of hydraulic networks and are executed by means of oscillating drives (for ex. AUMA) with telemetric control with transmission of drive operational status.